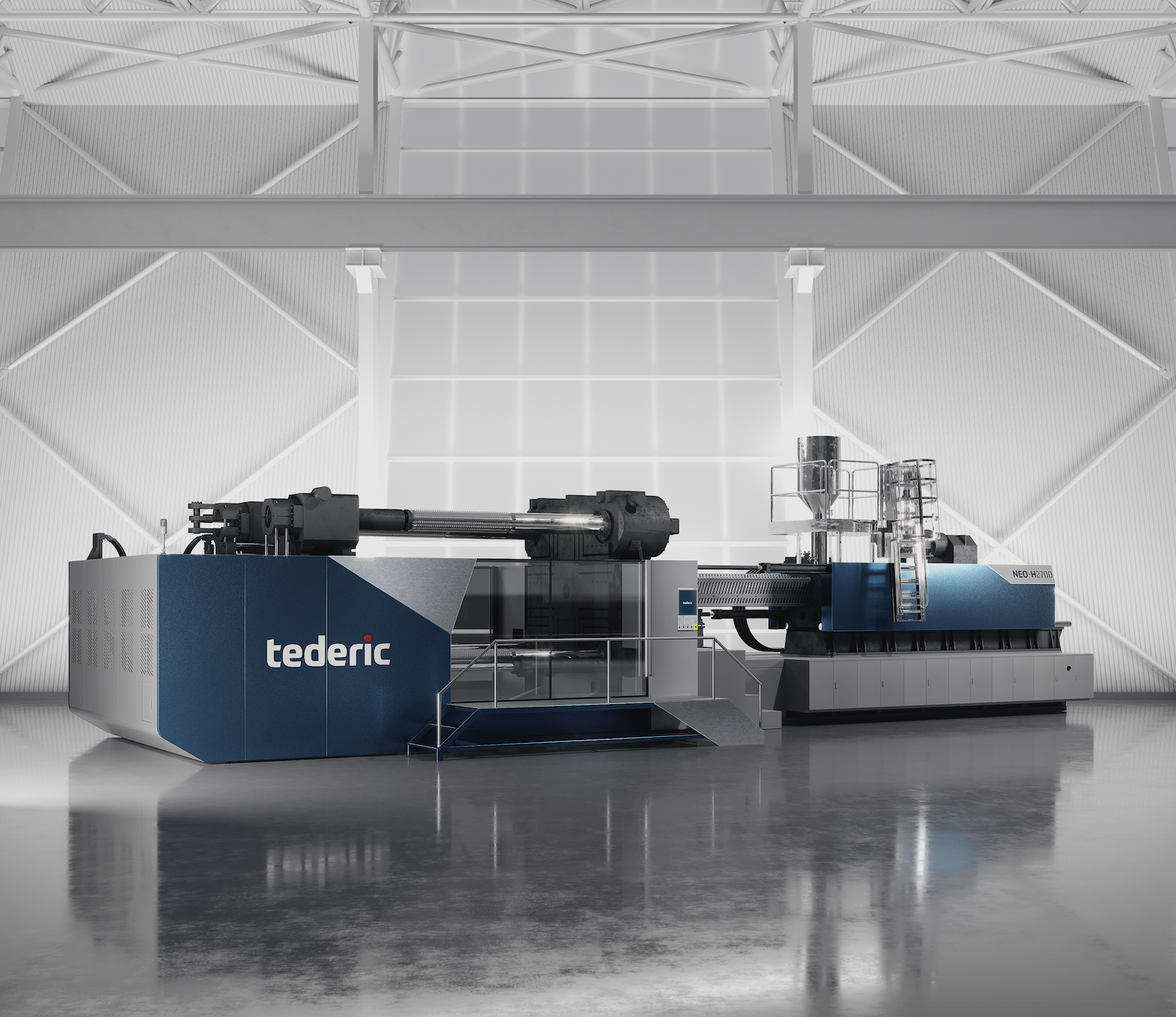

NEO H Series

Tederic is driving the future of injection molding, combining cutting-edge innovation with decades of industry expertise. The NEO·HII series showcases a range of patented technologies and versatile, high-performance configurations, delivering tailor-made solutions to meet the most demanding production requirements. The two-platen structure enables least footprint while maximizing mold dimensions.

With exceptional precision, efficiency, and reliability, the NEO·HII series seamlessly adapts to diverse manufacturing challenges, ensuring maximum productivity and sustainability.

Clamping force

4.800 – 70.000 kN

Power system

servohydraulic

Structure

two-platen

Control

KEBA

- Energy-Efficient Technology – Integrates an advanced servo-hydraulic system that optimizes power usage, reducing energy consumption while maintaining high output.

- Space saving two platen clamping unit

- Unmatched Precision – High-response servo motors and intelligent control systems enable precise injection molding, ensuring consistent part accuracy and repeatability (Injection weight repeatability ≤0.3%)

- The repeat accuracy of mold opening position is ≤1mm.

- Up to 70% energy saving

- Reliable & Durable Operation – Engineered for long-term stability, the NEO·H minimizes downtime and maximizes production efficiency.

- Fast & Flexible Performance – Shorter cycle times and adaptive control technology allow seamless handling of complex molding requirements.

Powered by KEBA, 15-inch next-generation touchscreen control offers an intuitive and highly responsive interface for effortless programming, in-depth system analysis, and precise adjustments. Designed for maximum user-friendliness, the advanced menu supports Hungarian and a wide range of selectable languages, ensuring seamless operation for global users. With cutting-edge automation and intelligent control, KEBA technology enhances efficiency, accuracy, and ease of use in every aspect of injection molding.

Typical NEO H Series applications

E-Charge™ Electric Preplasticizing Technology

E-Charge™ Electric Preplasticizing Technology revolutionizes the injection molding process by replacing the traditional hydraulic motor with a high-torque servo motor and gearbox drive system, ensuring precise and efficient plasticization.

Key Advantages:

High-Speed Performance – Significantly reduces loading and molding times, enhancing overall productivity.

Superior Energy Efficiency – Cuts power consumption by 15%-30% and water usage by 50% under the same production conditions.

Eco-Friendly Operation – Minimizes noise and eliminates hydraulic oil contamination, promoting a cleaner and more sustainable manufacturing environment.

With E-Charge™, manufacturers achieve faster cycles, lower operational costs, and a greener production footprint.

Seamless, Standardized Connectivity – Powered by EUROMAP & OPC UA

Modern production demands smart connectivity—and Tederic delivers. Our machines support EUROMAP 77, the industry-standard interface for data exchange between injection molding machines and higher-level production systems such as MES, ERP, and quality management platforms.

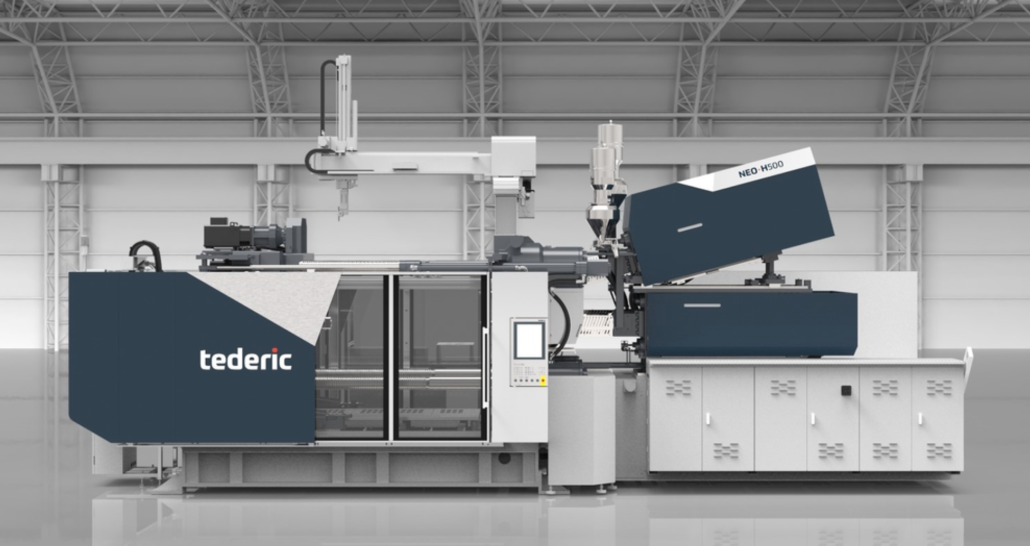

Seamless Automation—From One Trusted Partner

Elevate the performance of your Tederic injection molding machine with fully integrated automation—all from a single source. Whether it’s simple part removal or sophisticated post-molding assembly and packaging using advanced 6-axis robotics, we design and deliver complete turnkey production cells tailored to your specific needs.

-

Higher production efficiency

-

Reduced production costs

-

Streamlined communication with one dedicated point of contact for the entire system

Shaping Success with Quality & Service.

Contact us today and discover how you can take your business to the next level with Tederic injection molding machines and our premium service offerings!